Accurate Material Testing Lab: Your Relied On Companion

Wiki Article

Mechanical Testing Facility: Reviewing Material Performance

Are you interested regarding exactly how materials are tested for their performance in engineering? In this short article, we will explore the importance of product screening and the various mechanical examinations used to review product performance.Significance of Product Screening in Engineering

You need to recognize the value of material screening in design to guarantee the efficiency as well as reliability of your items. Product testing is a vital action in the design and also manufacturing procedure. By subjecting materials to various examinations, you can assess their mechanical residential or commercial properties as well as determine if they fulfill the needed criteria as well as specifications.

Product screening additionally permits you to ensure the dependability as well as durability of your items. By replicating real-life problems and also subjecting products to severe temperatures, humidity, and corrosive environments, you can evaluate their toughness as well as efficiency gradually. This assists you make notified choices concerning the products you pick for your items, preventing prospective failures and costly recalls in the future.

Material testing offers useful information that can be made use of to boost the layout as well as production process. By analyzing the outcomes of various tests, you can optimize the product choice, determine locations for enhancement, and boost the general high quality of your products.

Types of Mechanical Examinations for Assessing Product Performance

When it comes to reviewing product performance, there are several kinds of mechanical tests that can be conducted. One usual test is the tensile test, which gauges the stamina and ductility of a product by applying stress up until it breaks. An additional test is the compression examination, which examines a material's capacity to stand up to compressive forces.

Recognizing Material Properties for Screening

Comprehending the buildings of materials is essential for carrying out effective examinations. When you are evaluating product performance in a mechanical screening facility, it is essential to have a comprehensive understanding of the numerous homes that can influence the material's actions. One key residential or commercial property to take into consideration is the strength of the product, which describes its capability to hold up against applied pressures without damaging or deforming. Stamina is typically determined via examinations such as tension or compression tests, where the material undergoes pulling or pushing forces till it reaches its breaking point.One more crucial building is hardness, which refers to the material's resistance to impression or scratching. This property is important in identifying the material's capacity to stand up to deterioration. Hardness can be measured using various techniques, consisting of the Brinell or Rockwell firmness examinations.

Additionally, it is very important to think about the product's ductility, which is its ability to undertake plastic contortion without fracturing. Ductility is measured via tests like the tensile examination, where the material is stretched until it reaches its breaking point. This home is specifically essential in applications where the material requires to be bent or formed without breaking.

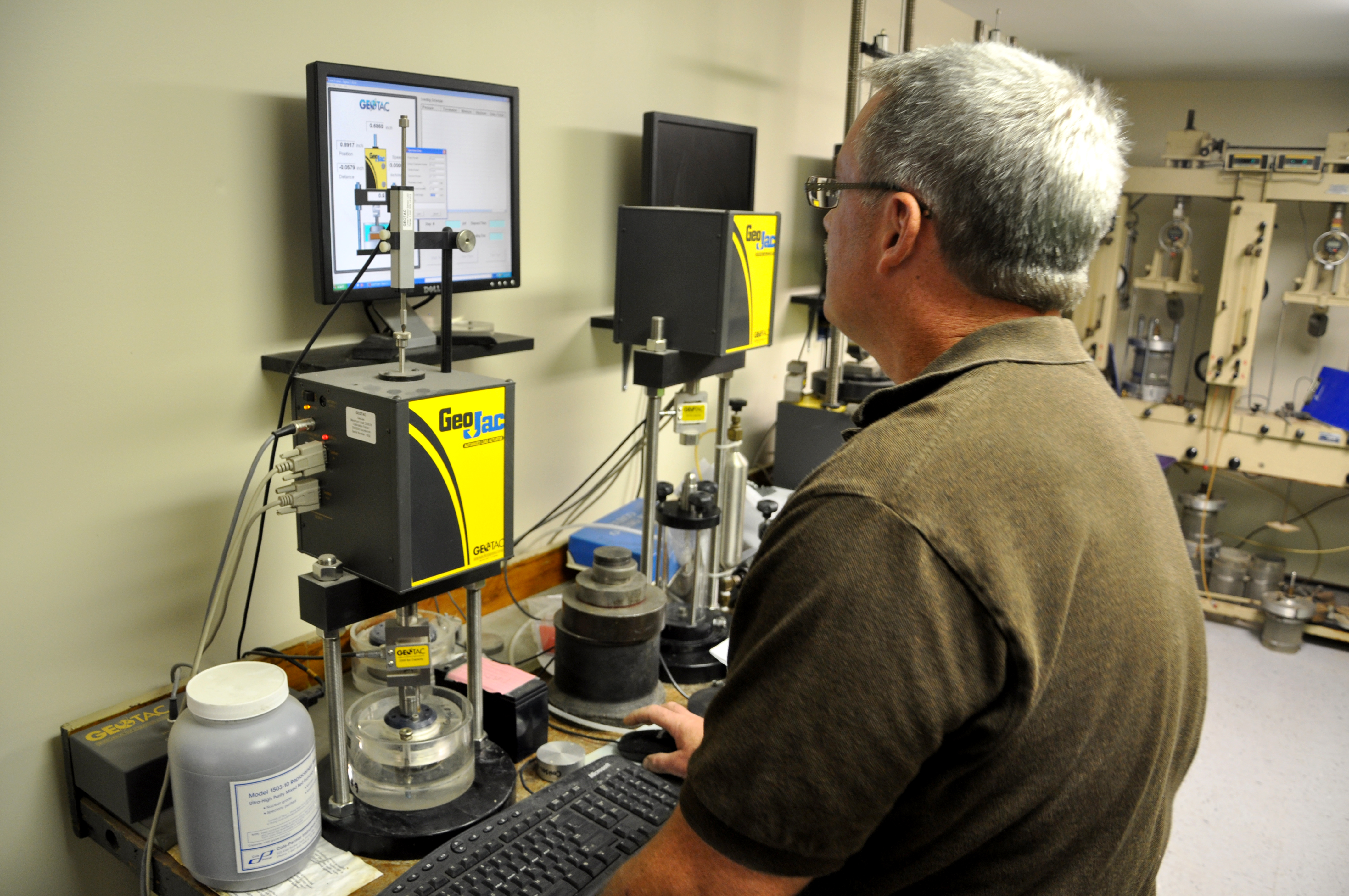

Equipment as well as Techniques Used in Mechanical Testing

To accurately analyze the homes of various products, it's vital to acquaint yourself with the equipment and methods utilized in mechanical screening. Tensile screening, for instance, includes stretching a product till it breaks to determine its stamina and also flexibility. By recognizing the tools and also strategies made use of in mechanical testing, you can successfully examine the efficiency of various materials.Interpreting as well as Analyzing Test Outcomes for Product Efficiency Analysis

When translating and analyzing examination results, you'll need to meticulously take a look at the data to establish exactly her latest blog how well the materials execute. These might show prospective issues or incongruities in the material's efficiency.Next, take into consideration the particular properties being examined and also contrast them to the preferred requirements or criteria. This can involve examining the screening methodology, example prep work, or also the material itself.

Conclusion

There you have it, comprehending the significance of material testing in design is vital for examining material efficiency. material testing lab. By performing different mechanical browse around this site tests, you can acquire valuable understandings right into the residential properties as well as behavior of different products. With the ideal equipment and methods, you can accurately gauge as websites well as evaluate examination outcomes to evaluate product efficiency. Make certain to prioritize product testing in your engineering jobs to guarantee optimum performance and also integrity.Report this wiki page